Las víctimas de la guerra amputadas en Jordania están recibiendo prótesis impresas en 3D gracias a un hospital de cirugía reconstructiva de Médicos Sin Fronteras. Esperan permitir que los pacientes recuperen la funcionalidad de las extremidades perdidas a un precio asequible. La impresión 3D ha demostrado ser extremadamente útil para desarrollar prótesis , los resultados no solo se adaptan a cada paciente y son ligeros, sino que también son rápidos y económicos de hacer.

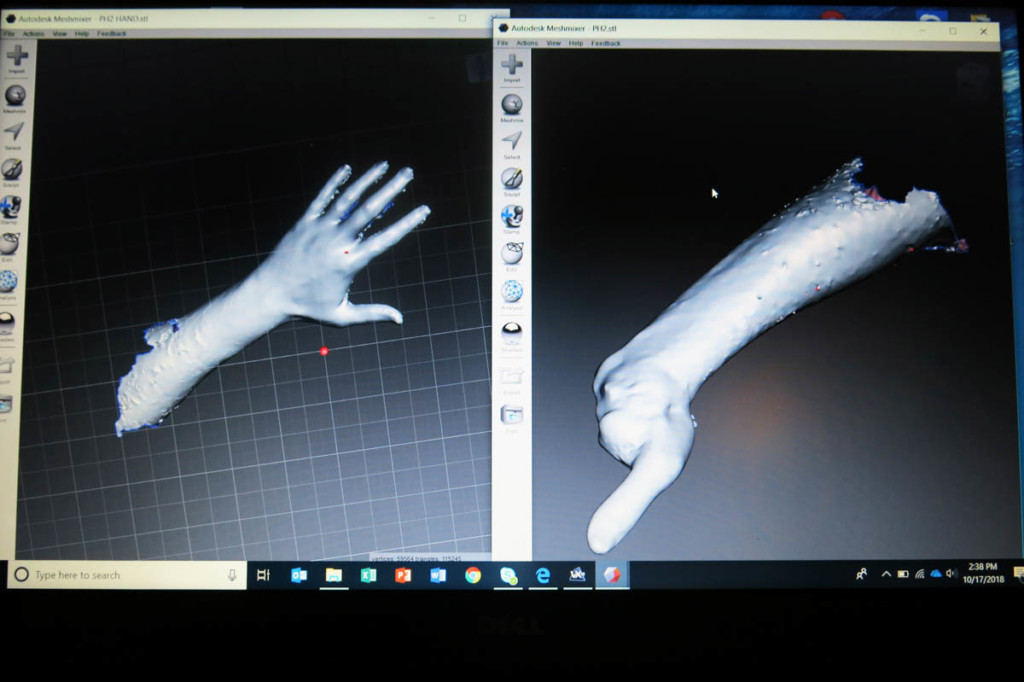

3D printing has proven itself to be extremely useful for developing prosthetics. Not only are the results customized to each patient and lightweight, they’re also quick and cheap to make.

Two years ago, an Amman-based Doctors Without Borders (translated and shortened to MSF in French) hospital began a 3D project and studied how the technology could improve the lives of patients.

As a result, amputee war victims from across the Middle East are being provided with 3D printed prosthetics. Although still in its experimental phase, there have been positive uses so far and patient feedback helps to improve the prosthetics created for others. Pierre Moreau, the clinical coordinator for the 3D project, said:

“The MSF Foundation launched the 3D project in Amman in February last year, and we started to see the first patients two months later. So far, we have delivered 16 printed prosthetics. But our role doesn’t stop here. We support patients through a string of occupational therapy sessions to show what they can do with them.”

3D Printing Prostheses and Changing Lives

Although the 3D printing project is just two years old, the Amman-based hospital has been operating for over ten years. Patients predominantly come from Yemen, Syria, Iraq, Gaza, and other places where hospital treatment is unaffordable.

Already, doctors have seen the benefits of lightweight prosthetics by the fact that patients actually use them. Patients explained that traditionally made prosthetics are too heavy and ineffective for carrying out every-day tasks.

Furthermore, it would cost up to $2,000 to create a below-elbow prosthetic. Thanks to 3D printing technology, it’s possible to print one from thermoplastic polyurethane for a price of $50 or under.

Altogether, the price of a prosthetic including a doctor’s assessment and evaluation as well as the printing time costs up to $250. Doctors use a 3D scanner and technicians can 3D print prostheses anywhere there is a printer. However, this price is likely to decrease with the development of new materials and cheaper printers.

“The idea is to be able to produce 3D printed prosthetics in the future in places difficult to access and lacking a sound healthcare system, like in conflict areas. But the way to do it is still under discussion, as it is not always easy to find technicians available in these areas, and printers are still expensive,” explains Moreau.

Fuente: https://all3dp.com