El documento adjunto analiza el importante papel de la tecnología de impresión 3D en la fabricación militar e industrial moderna, particularmente en la fabricación de explosivos y propulsantes, al permitir un control preciso del rendimiento y una formación precisa de la estructura, transformando los métodos de fabricación tradicionales. La clave de esta innovación son los adhesivos y aglutinantes utilizados en el proceso, que determinan las tasas de formulación y la integridad estructural.Se describen cuatro tecnologías principales de impresión 3D adecuadas para explosivos y propulsantes: fotopolimerizaci

Abstract

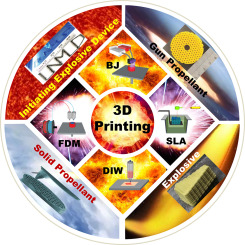

3D printing technology is considered the perfect modern manufacturing technology for military/industrial enterprises worldwide. Applying 3D printing in explosive and propellant fabrication enables precise performance control and accurate structure formation, revolutionizing traditional manufacturing concepts and improving continuous, automated, integrated, and flexible explosive and propellant manufacturing. As key components in the 3D printing of explosives and propellants, adhesives/binders play a crucial role in determining the formation rate, stability, and structural integrity of explosive formulations. This paper provides an overview of the four major 3D printing technologies suitable for explosive and propellant manufacturing: vat photopolymerization, binder jetting, fused deposition modeling, and direct ink writing, with their typical production processes, technical characteristics, principles, and limitations discussed. Specific solutions to the limitations of vat photopolymerization (printing speed), binder jetting (low accuracy and limited applicable materials), fused deposition modeling (poor mechanical properties and dimensional stability), and direct ink writing (product performance defects) are presented. Additionally, future development directions and prospects for the 3D printing of explosives and propellants are discussed, thus providing valuable insights into the application of 3D printing technology in the fields of explosives and propellants.

![]() Fuente: https://www.sciencedirect.com

Fuente: https://www.sciencedirect.com